Loctite 3D 3955 Resin

LOCTITE 3D 3955 is a non-halogenated material that delivers superior performance and high modulus, boasting impressive flexural and tensile properties. This material meets the UL94 V-0 standards for flammability and fulfils FST criteria (AITM2-0002, AITM2-0007, AITM3-0005), making it resilient in extreme conditions with minimal deformation due to its high Heat Deflection Temperature (HDT).

Key Mechanical Properties

- Shore Hardness D: 82

- Flexural Modulus (MPa): 4,600

- Elongation at Break (%): 2

- Young’s Modulus (MPa): 3,600

- Tensile Stress at Break (MPa): 67

Key Benefits

- Fire Safety Material

- Halogen Free

- Excellent Flexural and Tensile Physical Properties

Ideal Applications

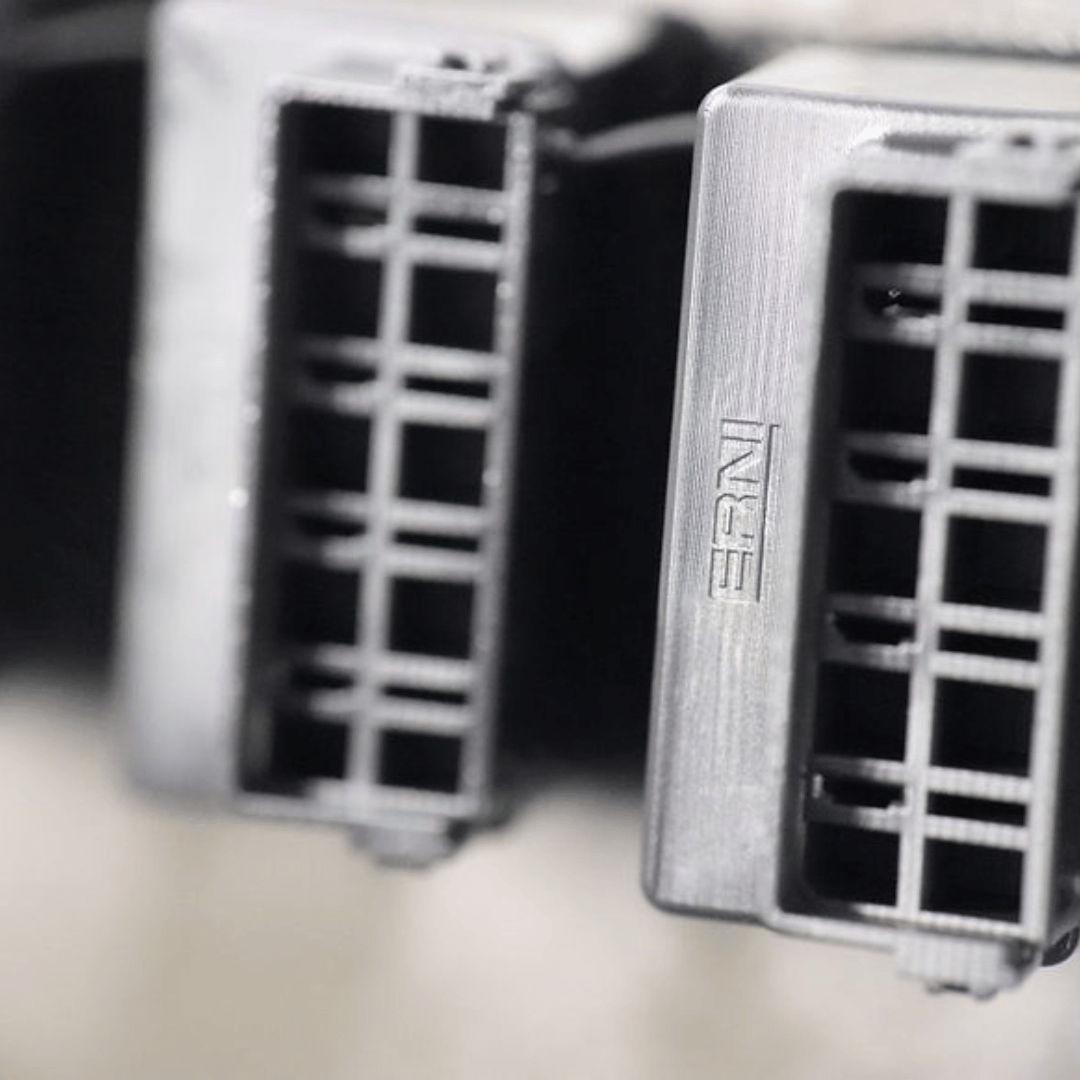

- HVAC Components for Aircraft

- Clips and Plugs for Control Systems/Cabinets

- Connectors, Electronic Housings

Pre-Melt Requirements

LOCTITE 3D 3955 BK requires pre-melt of material before use. It is recommended to heat it in the provided 1kg container at 80°C for 4 hours or until the resin is fully liquified in the container. Shake container before pouring material into tray.

Pre-Melt material should be kept at 60°C to maintain fluidity and should be used within 2 weeks of melting for best results.

Important Information

- User must wear suitable respiratory protection during cleaning process.

- Note: Glycol Ether TPM can be used in lieu of Loctite 3D Cleaner T

- Glycol Ether TPM oxidizes at elevated temperatures over time. Consult the MSDS of TPM and contact the supplier for further guidance. Use appropriate antioxidants and regularly measure peroxide concentration.